astm rockwell hardness test|rockwell hardness test theory : mfg Standard Test Methods for Rockwell Hardness of Metallic Materials. Significance and Use. 4.1 The Rockwell hardness test is an empirical indentation hardness test that can . webSeleccione de la lista para identificar el controlador apropiado para su producto NVIDIA. Opção 2: Automaticamente localizar drivers para meus produtos NVIDIA. Pesquisar .

{plog:ftitle_list}

Resultado da We would like to show you a description here but the site won’t allow us.

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges . Standard Test Methods for Rockwell Hardness of Metallic Materials. Significance and Use. 4.1 The Rockwell hardness test is an empirical indentation hardness test that can .Rockwell superficial hardness tests. The significant differences between the two tests are that the test forces are smaller for the Rockwell superficial test than for the Rockwell test. The . The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .

Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .

Standard Test Methods for Rockwell Hardness of Metallic Materials. 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation .Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and .Rockwell hardness test metals; Rockwell hardness test sesuai ISO 6508 / ASTM E18. . Dengan bantuan kedalaman lekukan permanen h, Rockwell hardness (HR) kemudian dapat dihitung menurut rumus yang ditentukan .

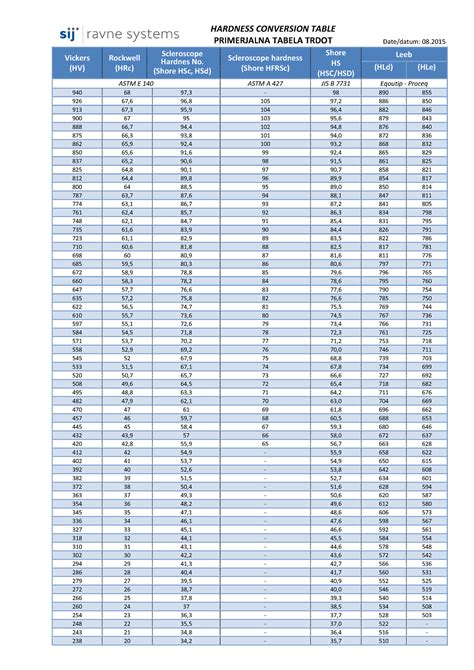

scleroscope hardness conversion chart

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .ASTM International standards E 10, Test Method for Brinell Hardness of Metallic Materials, and E 18, Test Methods for Rockwell Hardness of Metallic Materials, have both recently undergone extensive revisions.Both standards are under the jurisdiction of Subcommittee E28.06 on Indentation Hardness Testing, which is part of ASTM International Committee E28 on .

We would like to show you a description here but the site won’t allow us.ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application.

wood moisture meter accuracy test

ASTM E 18-07 Standard Test Methods for Rockwell Hardness of Metallic Materials is the active and current standard by which Rockwell Hardness Testing is performed, and is also the most frequently used hardness testing method. Significance and Use 4.1 The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical . Standard Test Methods for Rockwell Hardness of Metallic Materials E0018-20 ASTM|E0018 .This post references the ASTM Rockwell hardness standard test and will teach you all you need to know. I. Significance of Rockwell Hardness Standard Test To correlate the wear and resistance, tensile strength, elasticity, and other physical characteristics of metallic materials, the Rockwell Hardness Test, an empirical hardness test, is used.hardness tests - the Rockwell test is a measure of the resistance of material, specifically metals, to permanent indentation. Indentation hardness is not a fundamental . Rockwell testing is covered by ASTM test method E 18. While all indentation hardness tests generally serve the same purpose, each one has definite advantages that make

The standard superficial Rockwell 15Y hardness test has been adapted for use on concrete. Hardness measurements were made on the mortar regions between the coarse aggregate pieces. A correlation between this hardness and the concrete's compressive strengt . ASTM grants Licensee a limited, revocable, nonexclusive, non-transferable license to .appendixes which relates to the Rockwell hardness test. List of ASTM Standards Giving Hardness Values Corre-sponding to Tensile Strength Appendix X1 Examples of Procedures for Determining Rockwell . Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), ASTM E18 is the industry standard for Rockwell hardness testing of metallic materials. This specification includes both theory and standard practice statements. For those companies Nadcap accredited in heat treat where the AC7102/5 for hardness and conductivity testing is included, an additional layer of requirements come into play.

4.1 A Rockwell hardness number is a number derived from the net increase in depth impression as the load on an indenter is increased from a fixed minor load to a major load and then returned to a minor load (Procedure A). A Rockwell alpha (α) hardness number represents the maximum possible remaining travel of a short-stroke machine from the net .

The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from . Standards: DIN EN ISO 6506 / ASTM E10 Brinell Methods 2.2 Method Indenter Load F kg Load F N Load Factor 0.102 x F/D2 Hardness Range HBW* Material Revision of E18-22 Standard Test Methods for Rockwell Hardness of Metallic Materials. . ASTM Standard C33, 2003, "Specification for Concrete Aggregates," ASTM International, West Conshohocken, PA, 2003, DOI: 10.1520/C0033-03, www.astm.org. Referencing Standards (multiple revisions in same year): .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for Rockwell hardness testing (Part B) and the calibration of .

Rockwell hardness testing machine by having tighter tolerances on certain parameters. 3.1.7.3 portable Rockwell hardness testing machine—a Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the Rockwell indentation hardness test principle. 3 .5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial

Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, ASTM E384) and Vickers hardness test (ISO 6507, ASTM E92, . Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf .

ASTM Hardness Standards Reference Guide . Standard Test Method for Macro-Rockwell Hardness Testing of Metallic Materials: F1957 : Standard Test Method for Composite Foam Hardness-Durometer Hardness . JOIN THE CONVERSATION. INDUSTRIES. Automotive Components Testing Solutions

The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.The Rockwell hardness test has a variety of applications. It is not only used to determine material properties according to hardness and forming processes, but also for quick and effective testing in production and incoming goods departments. . All Rockwell methods to EN ISO 6508, ASTM E18; Non-standard methods in Brinell HBT in a load range .Rockwell hardness testing and ASTM E18 standards. Hardness is defined as a material’s resistance to permanent indentation. Current Rockwell hardness test methods are specified in ASTM E-18 and anyone wishing to perform a Rockwell Hardness test should become familiar with this test standard.

rockwell hardness testing chart

wood moisture meter aldi

wood moisture meter amazon uk

WEBAnimefox - Watch Free Anime Online. Stream your favorite anime shows and movies for free. Explore a vast collection of high-quality anime content.

astm rockwell hardness test|rockwell hardness test theory